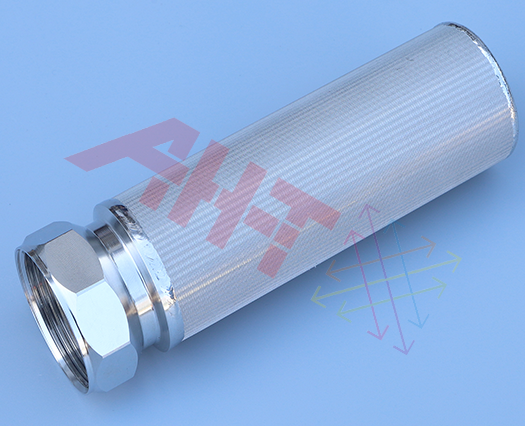

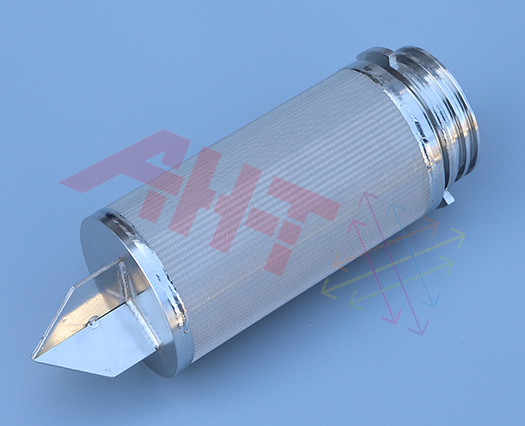

Sintered metal filters are made of metal, which gives them many advantages over other types of filtration media, such as PTFE or ceramics. The widely used and standard combination is 5-layer sintered wire mesh, it is combined by five different layers or multi-layer of stainless steel wire mesh, and then sintered together through being vacuum sintered, compressed, and calendared, forming a porous product. Sintered wire mesh is made from multiple layers of woven wire mesh panels using a sintering process. This process combines heat and pressure to permanently bond multi-layers of mesh together. The same physical process used to fuse individual wires together within a lover of wire mesh is also used to fuse adjacent layers of mesh together. This creates a unique material offering excellent mechanical properties, it is ideal material for purification and filtration.

High precision and high particle removal efficiency

The AHT sintered metal filter has a uniform pore distribution in the range of 0.5 to 300 microns, ensuring efficient removal of fine particles and high precision filtration requirements.A wide selection of materials (such as stainless steel, bronze, nickel, etc.) is available, as well as customized services in different shapes and sizes to meet the needs of specific applications.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom metal sintering filter manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of metal sintering filter customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Certified raw material procurement

Plastic film & Plywood case

1) High polymer industry

*Filtration rate: 1-300μm

*Diameter: 14-800mm*Other diameters and lengths are available upon request

Stainless steel (304, 304L, 316, 316L, 904L, etc.): Strong corrosion resistance, suitable for a variety of chemical environments.

Bronze: Good mechanical properties and electrical conductivity.Other alloys: Available according to specific requirements, such as titanium alloys.

Single and multilayer: Offers different strength and filtration accuracy options.

Woven wire mesh: High flexibility for filters with complex shapes.Sintered pore structure: Provides a larger filter surface area.

To adapt to different application conditions and installation requirements, AHT offers a variety of adapter options.

Standard connector (215, 222, 226)