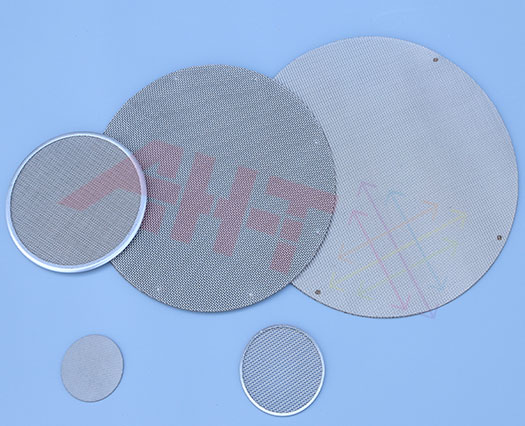

Stainless Steel Filter Discs

The stainless steel filter discs refers to the circular extruder filter commonly used in cylindrical extruders for changing the screen. The filtering medium is a multi-layer sintered fabric. Hatong, as the professional stainless steel filter discs manufacturer, offers both single-layer and multi-layer circular extruder filters, with various materials and sizes available for selection. It has advantages such as a sturdy structure, excellent wear resistance and corrosion resistance, and long service life. It is widely used in fields such as filtering corrosive gases and liquids, fuel filtration, etc. At the same time, we can ensure that all processes from the manufacturing of sintered raw materials, cutting, subsequent processing of the sintered filter elements, and final testing can be independently completed. If you are interested in further discussing the technical details of stainless steel filter discs or cooperation opportunities, please feel free to contact us at any time.

Stainless Steel Filter Discs Features and Advantages

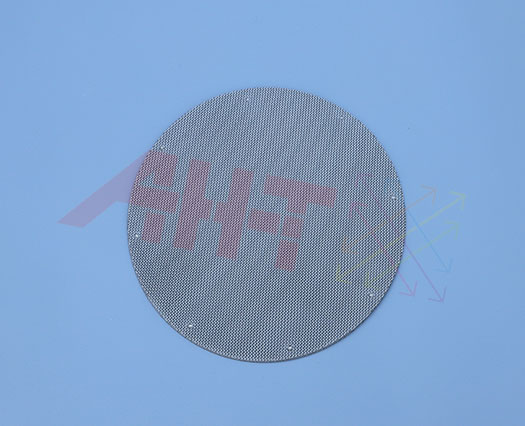

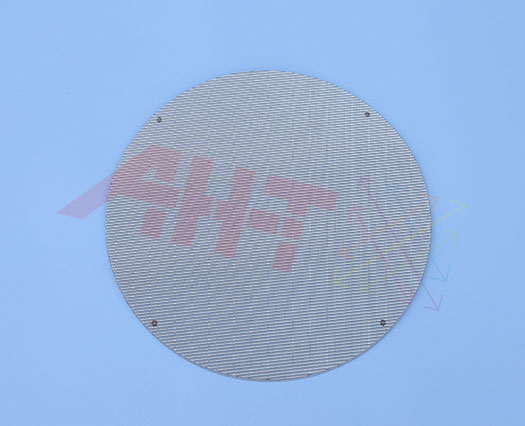

Good filtration performance, high filtration accuracy

Good rigidity, high strength

Stainless steel filter discs structure is strong, has excellent tensile resistance, can withstand greater pressure, not easy to deformation and rupture;

Easy to clean and recyclable

Stainless steel filter discs are easy to clean, recyclable, and can reduce operational maintenance costs through repeated cleaning.

Stainless Steel Filter Discs Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom stainless steel filter discs manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of stainless steel filter discs customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Stainless Steel Filter Discs Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Stainless Steel Filter Discs Packaging

Plastic film & Plywood case

Stainless Steel Filter Discs Applications

Stainless steel filter discs are mainly used in the absorption, evaporation and filtration process in petroleum, chemical, medicine, metallurgy, machinery, ships and automobiles to delete the mist drop or liquid foam or used as air filter in cars and trucks.

Stainless Steel Filter Discs Specifications

*Filtration rate: 3-200μm

*Diameter: 10-3000mm

*Other diameters and lengths are available upon request

Stainless Steel Filter Discs shape

Available in round, square, rectangular, oval, U shape and other shapes.

Other special shapes are available.

Stainless steel Filter Discs Structure Type

Single-layer extruder filters are widely used in plastics and film blowing industries, where raw material pollution is low, and the pressure inside the machine head is low;

Multi-layer extruder filters are commonly used in the plastics, fiber, and polymer industries, where fine filtration is required to prevent the mixing of foreign objects.

Stainless Steel Filter Discs Material

Stainless steel (304, 304L, 316, 316L, 904L, etc.): Strong corrosion resistance, suitable for a variety of chemical environments;

Bronze: Has good mechanical properties and electrical conductivity;

Nickel: Has good stability in high temperature environment;

Other alloys: Customized to your specific needs.

These are regular stainless steel filter discs specifications and can be customized to meet your specific filtration needs.