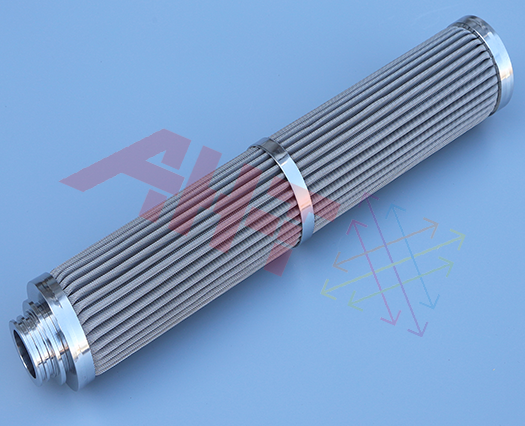

Stainless steel Pleated Filter

The stainless steel pleated filter element is formed by repeatedly pleated metal wire meshes of different diameters, The surface area of the wire mesh is large, allowing it to be installed in a compact housing, The pleated design's gap structure provides a larger filtration area. When fluid passes through, particles and impurities in the fluid will be retained on the surface or inside the stainless steel pleated filter element. This design can achieve very fine filtration and has features such as good strength, low detachment, easy cleaning, and good air permeability. To ensure the stability and structure of the filter, the supporting net is usually made of stainless steel or other corrosion-resistant metal materials. At the same time, adding two end covers not only helps with the connection of the stainless steel filter element but also strengthens its overall structure, ensuring stability, reliability, and sealing during use. As a stainless steel filter elements manufacturer, we closely collaborate with original equipment manufacturers to provide customized solutions for their assembly lines, ensuring compliance with specific technical standards and performance requirements, from material selection to the preparation of factory parts to achieve the highest assembly efficiency. If you are interested in further discussing the technical details of the stainless steel pleated filter element or cooperation opportunities, please feel free to contact us at any time.

Stainless steel Pleated Filter Features and Advantages

High precision and high particle removal efficiency

The AHT/Hatong pleated metal filter has a uniform pore distribution in the range of 0.5 to 300 microns, ensuring efficient removal of fine particles and high precision filtration requirements.

High temperature resistance

The corrugated metal structure allows the filter to withstand high temperatures up to 800℃ and is particularly suitable for high temperature gas filtration applications.

Stable shape, good impact resistance

Its robust construction guarantees stability and long service life in high-pressure and highly corrosive environments.

Excellent mechanical strength

Excellent impact resistance to harsh environments.

Good air permeability, consistent filtration efficiency

High porosity and good permeability reduce pressure drop, improve filtration efficiency, and can handle large volumes of impurities, extend replacement cycles, and save overall costs.

Excellent unloading strength

AHT filters maintain strong unloading capacity even in high pressure and corrosive environments, ensuring continuous and reliable filtration performance.

Easily machined into various shapes and welded

Pleated metal materials are easy to process and can be customized to various shapes and connection sizes according to customer requirements providing highly flexible solutions.

Various materials, shapes and connection sizes can be customized

A wide selection of materials (such as stainless steel, bronze, nickel, etc.) is available, as well as customized services in different shapes and sizes to meet the needs of specific applications.

Stainless steel Pleated Filter Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom Stainless steel Pleated Filter manufacturer, the plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of Stainless steel Pleated Filters customization, has reached a strategic partnership with more than 60 countries in the world, welcome to inquire and sample request.

Stainless steel Pleated Filter Quality Control

Certified raw material procurement

There are professional inspectors for each production process

Advanced production equipment

All AHT Stainless steel Pleated Filters are subject to rigorous quality testing before leaving the factory

Stainless steel Pleated Filter Packaging

Stainless steel Pleated Filters

Stainless steel Pleated Filter Applications

1) High polymer industry

2) Petrochemical industry

3) Pharmaceutical and food refining industry

4) Water treatment

5) Machinery and vessel industries

6) Air purification

7) Others: high temperature, high viscosity, high pressure

Stainless steel Pleated Filter Specifications

* Filtration rate: 1-300um

* Diameter:14-800mm

* Length:35-1500mm

* Other diameters and lengths are available upon request

Stainless steel Pleated Filter Material Selection

Stainless steel (304,304L,316,316L,904L,etc.) : strong corrosion resistance, suitable for a variety of chemical environments.

Bronze: Good mechanical properties and electrical conductivity.

Nickel: Has good stability in high temperature environment.

Other alloys: Available according to specific requirements, such as titanium alloys.

Stainless steel Pleated Filter Structure Type

Single and multi-layer: Offers different strength and filtration accuracy options.

Woven wire mesh: High flexibility for filters with complex shapes.

Perforated metal: Enhanced mechanical strength, suitable for high pressure environments.

Pleated pore structure: Provides a larger filter surface area.

Stainless steel Pleated Filter Disposition

To adapt to different application conditions and installation requirements, AHT offers a variety of adapter options.

Standard connector (215,222,226)

Thread connector (M20,M30,M32,M42,etc.) Flat/DOE type.

The above are the common specifications of the general pleated wire mesh filter, and the specific specifications will be customized according to the customer's requirements to meet the specific filtration requirements and process conditions.